Welcome to the comprehensive guide for DeWalt planer manuals, designed to help you optimize your woodworking experience. These manuals provide detailed insights into operation, safety, and maintenance, ensuring you get the most out of your DeWalt planer.

Whether you’re a professional or a hobbyist, understanding your DeWalt planer’s capabilities and proper usage is key to achieving precise results. This guide covers everything from setup to troubleshooting, helping you master your tool effortlessly.

1.1 Overview of DeWalt Planers

DeWalt planers are professional-grade power tools designed for precise wood planing, offering reliability and efficiency for woodworking projects. These planers are known for their portability and robust construction, making them ideal for both workshop and on-site use. Popular models like the DW733, DW735, and DW734 feature powerful motors, durable cutterheads, and advanced dust management systems. The DW735, for instance, boasts a 15-amp motor capable of 20,000 RPM, while the DW733 is praised for its ease of use and maintenance. Designed with ergonomic handles and sturdy bases, DeWalt planers ensure stability and control during operation. Their versatility accommodates various woodworking needs, from smoothing wide boards to handling intricate details, making them a favorite among professionals and hobbyists alike.

1.2 Importance of Reading the Manual

Reading the DeWalt planer manual is crucial for safe and effective operation. It provides essential safety guidelines, such as wearing eye protection and ensuring proper blade installation. The manual also outlines specific instructions for handling sharp cutterhead knives and maintaining the tool. By understanding the manual, users can prevent accidents and ensure optimal performance. It covers setup, calibration, and troubleshooting, helping users avoid common errors. Regular maintenance, like lubrication and blade replacement, is also detailed to extend the tool’s lifespan. Ignoring the manual could lead to improper use, potentially causing damage or injury. Always refer to it before operating your DeWalt planer to maximize efficiency and safety in your woodworking projects.

Safety Guidelines and Precautions

Always wear eye protection and a dust mask when operating a DeWalt planer. Ensure blades are securely mounted and follow proper handling procedures to avoid injury. Regularly inspect the tool for damage and maintain a clean workspace to prevent accidents.

2.1 General Safety Tips for Planer Operation

Always read the manual before operating a DeWalt planer to understand safety protocols. Wear eye protection and a dust mask to prevent injury from debris. Ensure the workspace is clean and free from obstructions to avoid accidents. Keep loose clothing and long hair tied back to prevent entanglement with moving parts. Never operate the planer with damaged or dull blades, as this can lead to unpredictable behavior. Maintain a firm grip on the workpiece and avoid overreaching. Ensure the planer is placed on a stable, level surface to prevent tipping. Keep children and bystanders away from the work area. Properly store the planer when not in use to avoid unauthorized access.

Regularly inspect the tool for wear or damage, and ensure all guards are in place. Follow proper procedures for blade replacement and maintenance to maintain safety and performance. Always disconnect the power source before performing any adjustments or repairs. Adhere to these guidelines to ensure safe and efficient operation of your DeWalt planer.

2.2 Specific Safety Precautions for DeWalt Planers

DeWalt planers require adherence to specific safety precautions to ensure safe operation. Always wear safety goggles and a dust mask to protect against flying debris and dust. Keep hands and fingers away from the cutterhead while the planer is in operation. Never feed the workpiece in the opposite direction of the grain to avoid kickback. Ensure the planer is properly assembled and all parts are securely tightened before use. Regularly check the cutter knives for sharpness and proper alignment, as dull or misaligned knives can cause uneven planing and potential hazards. Use the provided handles to maintain control of the workpiece during operation. Avoid wearing loose jewelry or clothing that could get caught in the planer. Keep the work area well-lit to maintain visibility and prevent accidents. Always follow the manufacturer’s guidelines for blade replacement and maintenance to ensure optimal performance and safety. By adhering to these precautions, you can minimize risks and achieve professional-grade results with your DeWalt planer.

Key Features of DeWalt Planers

DeWalt planers are known for their robust motor power, efficient cutterhead design, and advanced dust management systems. They also feature portable and ergonomic designs for easy handling and precise results.

3.1 Motor Power and Speed

DeWalt planers are equipped with powerful motors designed to handle demanding woodworking tasks. The DW735 model, for instance, features a 15-amp motor capable of delivering up to 20,000 RPM, ensuring efficient material removal and smooth finishes. This high-speed operation allows for quick processing of even the hardest woods, making it ideal for professional use. The motor’s robust design ensures consistent performance, while its speed capacity provides versatility for various planing applications. With such impressive power and speed, DeWalt planers are reliable tools for achieving precise and professional-grade results in woodworking projects.

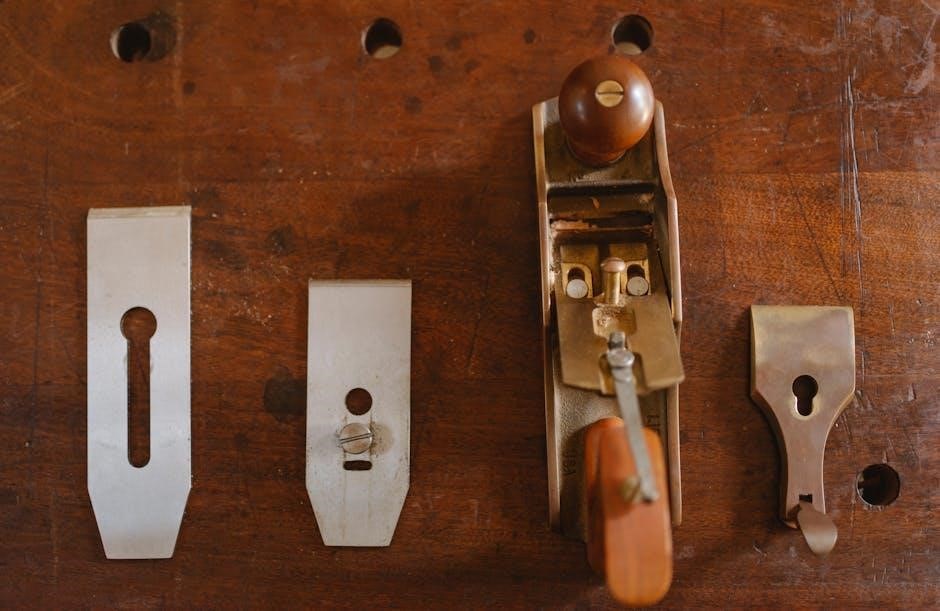

3.2 Cutterhead Design and Knife Replacement

DeWalt planers feature a robust cutterhead design that ensures precise and efficient planing. The DW735 model, for example, comes with three reversible knives, which provide a smoother finish and reduce the occurrence of snipe. These knives are strategically arranged to optimize material removal while maintaining accuracy. The cutterhead’s design minimizes vibration, allowing for consistent performance even during heavy-duty operations.

Knife replacement is a straightforward process, with easy-to-access components. Proper mounting and tightening of the knives are crucial for optimal performance, as outlined in the manual. Always handle the blades with care due to their sharpness, and refer to the manual for specific replacement procedures to ensure safety and maintain tool longevity.

3.3 Dust Management and Collection Systems

DeWalt planers are equipped with efficient dust management systems to ensure a clean and safe working environment. The DW735 model, for example, features a dust collection port that can be connected to a shop vacuum or a DeWalt dust extractor using an optional AirLock adapter. This setup significantly reduces dust and debris dispersion, making cleanup easier and improving visibility during operation. Proper dust management not only enhances workplace safety but also prolongs the lifespan of your planer by preventing dust buildup in internal components. Regular cleaning and maintenance of the dust collection system are essential for optimal performance, as outlined in the manual.

3.4 Portability and Ergonomic Design

DeWalt planers are designed with portability and ergonomics in mind, making them ideal for professionals and DIYers alike. The DW735 and DW733 models feature sturdy, foldable tables and lightweight yet durable construction, allowing easy transportation between job sites. Ergonomic handles are strategically placed for comfortable lifting and maneuvering, reducing strain during relocation. The planers’ compact design ensures they fit well in workshops or storage areas. Additionally, the balanced weight distribution enhances stability during operation, while the intuitive controls provide easy access for adjustments. These features collectively make DeWalt planers user-friendly and adaptable to various woodworking environments, ensuring efficient and comfortable use throughout projects.

Understanding the Manual Structure

The DeWalt planer manual is organized into clear sections, starting with a table of contents for easy navigation. It includes detailed technical specifications, diagrams, and safety guidelines to ensure safe and effective operation of your planer.

4.1 Table of Contents and Navigation

The DeWalt planer manual begins with a detailed table of contents, allowing users to quickly locate specific sections. This organized structure ensures easy navigation, covering essential topics such as safety guidelines, technical specifications, and maintenance procedures. Key sections include operation instructions, troubleshooting, and accessories, providing a comprehensive guide for optimal tool performance. The manual also features clear diagrams and step-by-step instructions, making complex processes understandable. By following the table of contents, users can efficiently find the information they need, ensuring safe and effective use of their DeWalt planer.

4.2 Technical Specifications and Diagrams

The DeWalt planer manual provides detailed technical specifications, ensuring users understand their tool’s capabilities and limitations. Key details include motor power, RPM, and knife configuration, essential for handling various woodworking tasks. Diagrams are prominently featured, offering visual guidance for assembly, maintenance, and operation. These visuals include exploded views of components and step-by-step instructions for tasks like knife replacement. The manual also highlights safety features, such as guards and emergency stop mechanisms, ensuring safe usage. By referencing these specifications and diagrams, users can optimize their planer’s performance, troubleshoot issues, and maintain the tool effectively, ensuring longevity and reliability in professional or DIY projects.

Maintenance and Upkeep

Regular maintenance ensures optimal performance and longevity of your DeWalt planer. This includes sharpening or replacing blades, cleaning debris, and lubricating moving parts to prevent wear and tear.

5.1 Blade Replacement and Sharpening

Proper blade maintenance is crucial for optimal performance of your DeWalt planer. Dull or damaged blades can lead to uneven finishes and increased risk of kickback. Always handle blades with care, as they are extremely sharp. For replacement, ensure the planer is unplugged and cool. Refer to your manual for specific instructions, as models may vary. Sharpen blades regularly using a high-quality sharpening stone or diamond file, maintaining the original bevel angle. Replace blades when wear or damage is evident, using only genuine DeWalt replacement knives for consistency and safety. After installation, tighten screws securely to the torque specified in the manual to prevent vibration and ensure accurate cutting. Regular blade upkeep extends tool life and enhances woodworking results.

5.2 Cleaning and Lubrication

Regular cleaning and lubrication are essential to maintain the performance and longevity of your DeWalt planer. Always unplug the tool before performing any maintenance. Use a soft brush or cloth to remove dust and debris from the cutterhead, tables, and exterior surfaces. Avoid using excessive water or harsh chemicals, as they may damage the finish or internal components. Lubricate moving parts, such as the rollers and adjustment mechanisms, with a high-quality silicone-based spray lubricant. Apply a small amount to avoid attracting dust. Refer to your manual for specific lubrication points and intervals. Proper maintenance ensures smooth operation, prevents corrosion, and extends the life of your planer.

Troubleshooting Common Issues

Address issues like vibration, uneven finishes, or blade wear by checking blade alignment, ensuring proper lubrication, and maintaining sharp blades. Consult the manual for detailed solutions to optimize performance and resolve common problems efficiently.

6.1 Common Problems and Solutions

Common issues with DeWalt planers include snipe, uneven finishes, and blade wear. To minimize snipe, ensure proper alignment of the knives and use consistent feed rates. For uneven finishes, check blade sharpness and adjust the depth setting. Blade wear can be addressed by sharpening or replacing knives as needed. Motor overload may occur due to excessive material thickness; allow the motor to cool before resuming operation. Regularly clean and lubricate moving parts to maintain performance. Always refer to the manual for specific troubleshooting steps and solutions to ensure optimal results and extend the lifespan of your DeWalt planer.

Accessories and Attachments

DeWalt planers offer various accessories like dust extraction adapters, optional knives, and stands, enhancing performance and usability. These attachments ensure efficient dust collection and improved tool versatility for woodworking projects.

7.1 Dust Extraction Adapters

Dust extraction adapters are essential for maintaining a clean and efficient workspace when using DeWalt planers. These adapters allow seamless connection to shop vacuums or DeWalt dust extractors, minimizing dust and debris dispersal. Models like the DeWalt DW735 are compatible with optional AirLock adapters, enhancing dust collection efficiency. Proper installation ensures optimal performance, reducing airborne particles and keeping your work area tidy. Regular cleaning of the adapter and collection system is recommended to prevent clogs and maintain airflow. Always follow the manual’s guidelines for attachment and usage to ensure safety and effectiveness. Using a dust extraction adapter not only improves air quality but also protects your tool from dust-related damage, prolonging its lifespan and reliability.

7.2 Optional Accessories for Enhanced Performance

Optional accessories for DeWalt planers can significantly enhance their performance and versatility. Dust extraction adapters, such as the DeWalt AirLock system, improve dust collection efficiency, reducing cleanup and maintaining a cleaner workspace. Infeed and outfeed tables extend material support, ensuring smoother operation and better control over larger workpieces. Mobile stands provide portability, allowing easy transportation of the planer between jobsites. Additionally, blade sharpening kits and replacement knives ensure optimal cutting performance. Accessories like remote switches offer convenience, enabling easy startup and shutdown without reaching the machine. These enhancements not only improve productivity but also extend the tool’s longevity, making them valuable investments for professionals and serious woodworkers.