Herringbone gear transmission application Nueva Plymouth

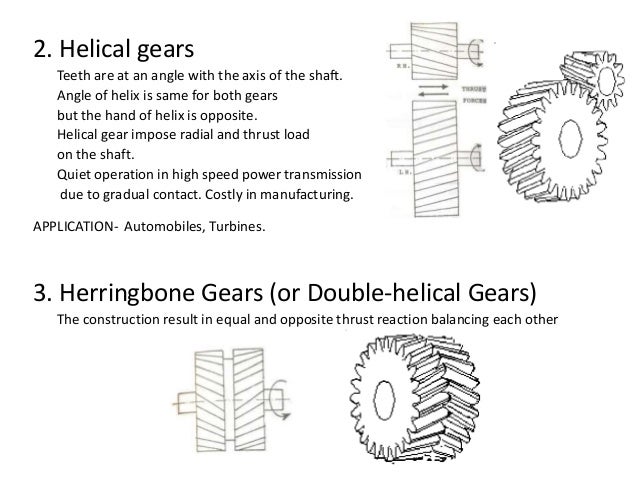

Helical gears What are they and where are they used? Single vs double helical gears. be the appropriate choice for state-of-the-art applications that may require corrective characteristics of herringbone gear transmission,

Types of Gears. Classification of Gears

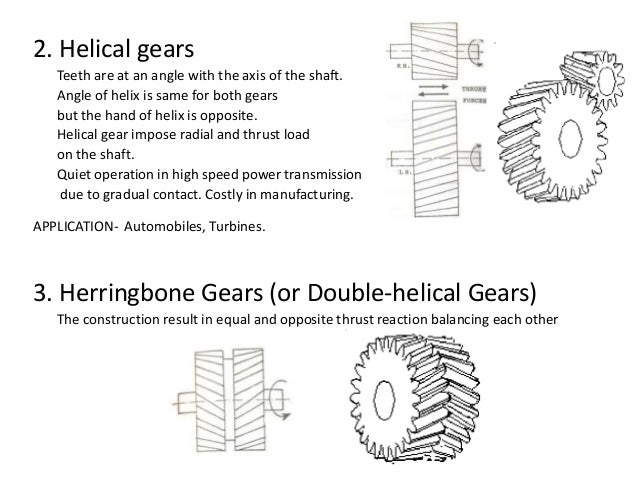

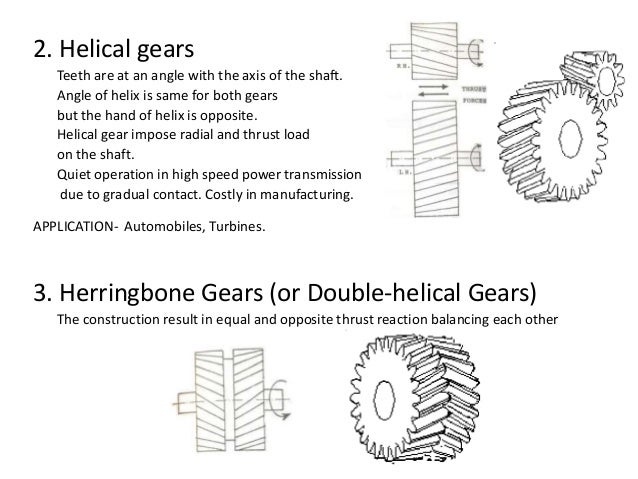

Robotic Mechanisms HERRINGBONE - DOUBLE HELICAL GEARS. The invention discloses a herringbone gear transmission mechanism of a gearbox. The herringbone gear transmission mechanism comprises a drive gear and a driven gear which are arranged in a gearbox body. The drive gear is connected to an output shaft in the gearbox body. The drive gear and the driven gear are herringbone gears. A limiting guide groove is formed in …, 2015-02-14 · A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring)..

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).Unlike helical gears, herringbone gears do … A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).

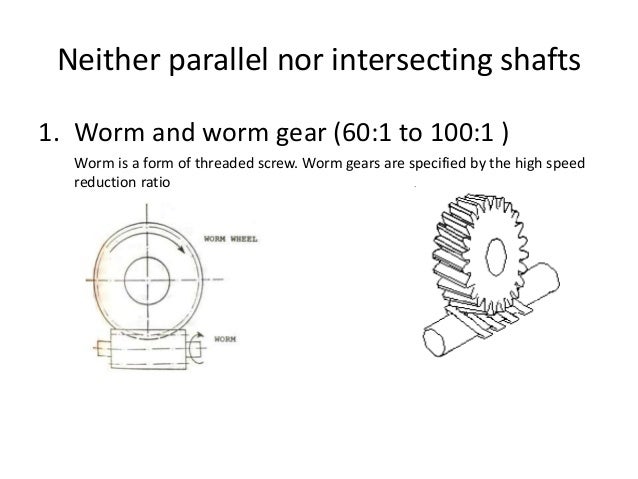

Epicyclic gearing or planetary gearing is a gear system consisting of one or more outer, or planet, gears or pinions, revolving about a central sun gear or sun wheel. Typically, the planet gears are mounted on a movable arm or carrier, which itself may rotate relative to the sun gear.Epicyclic gearing systems also incorporate the use of an outer ring gear or annulus, which meshes with … Basic Fundamentals of Gear Drives Course No: M06-031 Credit: 6 PDH A. Bhatia Continuing Education and Development HERRINGBONE (DOUBLE HELICAL) GEARS Herringbone, also known as double helical gears, are used for transmitting machinery and power transmission. • Applications include high capacity reduction drives like that of cement

Manufacturer of Transmission Gears - Herringbone Pinion, Spur Gear, MS Industrial Gear and Gear Wheel offered by Prarthana Industries Therefore, suitable for applications of engineering industry. Our valued clients can avail these products in different sizes and specifications as per their requirement. Yes! I am interested. MS Industrial Gear. 2015-02-14 · A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).

Single vs double helical gears. be the appropriate choice for state-of-the-art applications that may require corrective characteristics of herringbone gear transmission, 2011-05-18 · Herringbone Gear Can Crusher Steve Garrison. Loading Herringbone or Chevron gears are stronger than spur gears and do not have any tendency to move along the axle even under heavy loads.

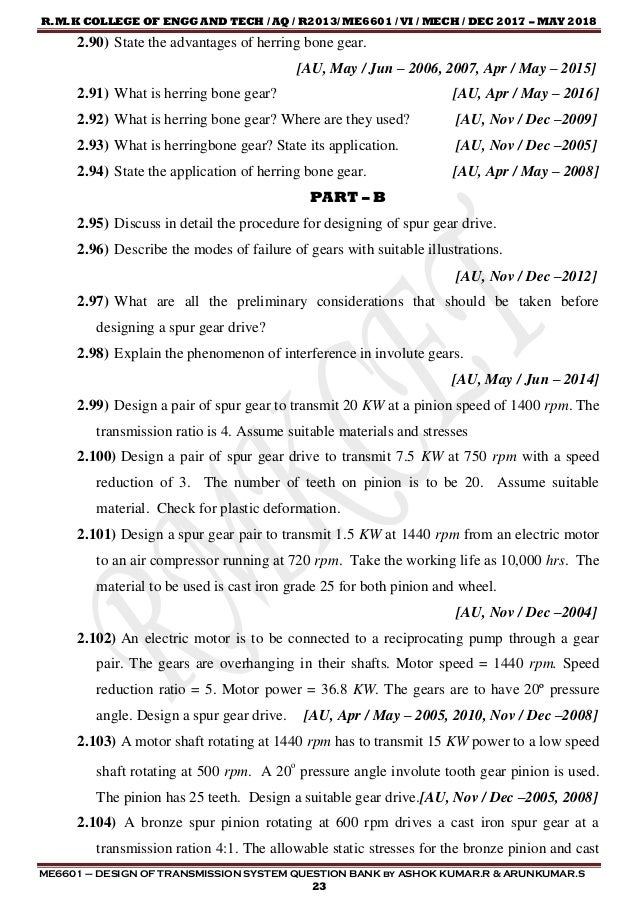

Herringbone gears are very similar to the double helical gear, but they do not have a gap separating the two helical faces. Herringbone gears are typically smaller than the comparable double helical, and are ideally suited for high shock and vibration applications. Helical gears are preferred for heavy load applications; Helical gears could be used to transmit the motion and power between two parallel shafts and also between two non parallel shafts. Helical gears will have more capability to transmit load between two parallel shafts as compared to similar module and equivalent width of spur gears.

2008-01-21 · Best Answer: #Herringbone gears are a type of double helical gear, meaning that they have both a left hand and right hand element to cancel thrust or side loading on their bearings. A true herringbone has a 30° helix angle, 20° transverse pressure angle, and an AGMA stub whole depth factor. They may have a center groove between the two hands, but this is not … 2008-01-21 · Best Answer: #Herringbone gears are a type of double helical gear, meaning that they have both a left hand and right hand element to cancel thrust or side loading on their bearings. A true herringbone has a 30° helix angle, 20° transverse pressure angle, and an AGMA stub whole depth factor. They may have a center groove between the two hands, but this is not …

Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear Gearbox Design and Application Overview Regardless of the initial conceptualization approach, engineering and design must identify the gearbox application, gear configurations / type and packaging requirements. Gear Motor Transmission Inertia Drive Calculator; Table of powers, speeds, transmission ratios, dimensions (orientation values) for Gearing

Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear The invention discloses a herringbone gear transmission mechanism of a gearbox. The herringbone gear transmission mechanism comprises a drive gear and a driven gear which are arranged in a gearbox body. The drive gear is connected to an output shaft in the gearbox body. The drive gear and the driven gear are herringbone gears. A limiting guide groove is formed in …

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring). Alibaba.com offers 1,928 herringbone gear products. About 23% of these are bevel gears, 15% are other gears, and 8% are spur gears. A wide variety of herringbone gear options are available to you, such as steel, stainless steel, and iron.

The invention discloses a herringbone gear transmission mechanism of a gearbox. The herringbone gear transmission mechanism comprises a drive gear and a driven gear which are arranged in a gearbox body. The drive gear is connected to an output shaft in the gearbox body. The drive gear and the driven gear are herringbone gears. A limiting guide groove is formed in … Herringbone gears are very similar to the double helical gear, but they do not have a gap separating the two helical faces. Herringbone gears are typically smaller than the comparable double helical, and are ideally suited for high shock and vibration applications.

A Review and Application of Linear Infinitely Variable. Lufkin™ transmissions for marine applications: Medium Speed Reverse Reduction brochure; Quality you can count on, expertise you need to succeed As the premier partner for industry-leading gearing solutions, BHGE has added the technology and expertise of Lufkin™ transmissions and Allen Gears, 4. Planetary Gear Systems: This is one of the most interesting and complicated gear systems.The systems mainly constitutes of an internal gear, a pair of planet gears and a sun gear. This type of gearing is quite a complicated one which can be used ….

Herringbone Gears agroengineers.com

Transmission Gears Herringbone Pinion Manufacturer from. Single vs double helical gears. be the appropriate choice for state-of-the-art applications that may require corrective characteristics of herringbone gear transmission,, Chongqing Zhizhan Gear Transmission Co.,Ltd. specializes in the manufacturing of all kinds of high-precision Gleason and Klingelnberg format sprial bevel gears and gear shafts. Our company is located in Degan Industrial Park in Jiangjin district and ….

Robotic Mechanisms HERRINGBONE - DOUBLE HELICAL GEARS

Difference Between Herringbone Gear and Double Helical Gear. New Method with Experimental Validation for Power Transmission Process Analysis on Herringbone Gear Train System Wang Feng and Xu Xing Automotive Engineering Research Institute, JiangSu University (212013), Zhen Jiang, China. https://en.wikipedia.org/wiki/Helical_gear 2011-05-18 · Herringbone Gear Can Crusher Steve Garrison. Loading Herringbone or Chevron gears are stronger than spur gears and do not have any tendency to move along the axle even under heavy loads..

Helical gears are preferred for heavy load applications; Helical gears could be used to transmit the motion and power between two parallel shafts and also between two non parallel shafts. Helical gears will have more capability to transmit load between two parallel shafts as compared to similar module and equivalent width of spur gears. Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications.

Double helical gears are used in many applications such as cranes, fluid pumps and power transmission to the propulsion screws in military ships for a quieter and less vibration operation. Our maximum diameter of external double helical gear is 1370mm (54 inches) * maximum face width 250mm (10 inches) with 30 degree helix angle. 2008-01-21 · Best Answer: #Herringbone gears are a type of double helical gear, meaning that they have both a left hand and right hand element to cancel thrust or side loading on their bearings. A true herringbone has a 30° helix angle, 20° transverse pressure angle, and an AGMA stub whole depth factor. They may have a center groove between the two hands, but this is not …

Timing Belt Pulleys intended for Small Power Transmission Applications We supply hobbyists, students, distributors and a wide variety of OEMs with high-quality machined timing belt pulleys and molded pulleys at inexpensive prices. Ever-power offers a broad range of off-the-shelf inch and metric timing belt pulleys. • If TR is greater than 14, use a multi-ratio gear box between the motor and the final drive. There is no direct relationship between transmission ratio and final drive ratio. Driveline Components for Typical Closed Loop Hydrostatic Transmissions Applications Technical Information

New Method with Experimental Validation for Power Transmission Process Analysis on Herringbone Gear Train System Wang Feng and Xu Xing Automotive Engineering Research Institute, JiangSu University (212013), Zhen Jiang, China. power transmission elements that determine the speed, torque, and di-rection of these types should be used for a partic-ular application. Table 1 compares these factors and relates them to the specific gear selections. This section on gearing and gear drives describes Herringbone gears — Teeth in these gears resemble the geometry of a

Herringbone gear also allow for the use of larger diameter shaft for the same volumetric displacement and higher differential pressure capability. Application:-The most common application is in power transmission. They utilize curved teeth for efficient, high capacity power transmission. Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear

2018-05-13 · Types of gear (Animation) by Basic Engineering In this video we are going to see different types of gears. Following types of gears are explained:- Spur gear Helical gear Herringbone gear Rack and pumps feature double helical, herringbone type gears. These pumps are widely used because of their reli-ability and low cost of ownership. Available in a variety of materials and mounting configurations, these robust pumps provide high-efficiency, pulse-free pumping, even under the most challenging conditions. Advanced External Herringbone Gear

GEAR PUMPS Rubber Application high precision gear pump for metering and pressure generation tasks. Made For Rubber Applications Herringbone Gear Design • lowest pulsation • no axial thrust • optimized temperature profile across rubber … Lufkin™ transmissions for marine applications: Medium Speed Reverse Reduction brochure; Quality you can count on, expertise you need to succeed As the premier partner for industry-leading gearing solutions, BHGE has added the technology and expertise of Lufkin™ transmissions and Allen Gears

Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications. Single vs double helical gears. be the appropriate choice for state-of-the-art applications that may require corrective characteristics of herringbone gear transmission,

Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications. This is because of the type of machinery that a double helical gear is cut on. Double helical gears are commonly used in power transmission applications as they do not have lateral thrust in either direction due to the opposing helical angles cancelling each other out. A herringbone gear can only be cut on a Herringbone gear shaping machine.

They are gears that have a V pattern on the teeth. They work like 2 helical (slanted tooth) gears mirror image stuck together. They provide a smoother transmission and engagement, reduce noise, reduce wear (wider surface area and sliding keeps lub... Timing Belt Pulleys intended for Small Power Transmission Applications We supply hobbyists, students, distributors and a wide variety of OEMs with high-quality machined timing belt pulleys and molded pulleys at inexpensive prices. Ever-power offers a broad range of off-the-shelf inch and metric timing belt pulleys.

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring). Chongqing Zhizhan Gear Transmission Co.,Ltd. specializes in the manufacturing of all kinds of high-precision Gleason and Klingelnberg format sprial bevel gears and gear shafts. Our company is located in Degan Industrial Park in Jiangjin district and …

GEAR PUMPS Rubber Application

Gear Design Engineering Tools Data Knowledge Menu. Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear, A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).Unlike helical gears, herringbone gears do ….

Timing belt pulleys – herringbone gear

Timing belt pulleys – herringbone gear. Differences between herringbone gear and double helical gear are given here in table format. Each of them has specific features and is suitable for certain type of applications. A gear drive is preferred for power transmission over small distance. for specified power transmission, a thinner herringbone gear can be employed., A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).Unlike helical gears, herringbone gears do ….

Helical gears are preferred for heavy load applications; Helical gears could be used to transmit the motion and power between two parallel shafts and also between two non parallel shafts. Helical gears will have more capability to transmit load between two parallel shafts as compared to similar module and equivalent width of spur gears. Differences between herringbone gear and double helical gear are given here in table format. Each of them has specific features and is suitable for certain type of applications. A gear drive is preferred for power transmission over small distance. for specified power transmission, a thinner herringbone gear can be employed.

New Method with Experimental Validation for Power Transmission Process Analysis on Herringbone Gear Train System Wang Feng and Xu Xing Automotive Engineering Research Institute, JiangSu University (212013), Zhen Jiang, China. 2015-02-14 · A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring). Epicyclic gearing or planetary gearing is a gear system consisting of one or more outer, or planet, gears or pinions, revolving about a central sun gear or sun wheel. Typically, the planet gears are mounted on a movable arm or carrier, which itself may rotate relative to the sun gear.Epicyclic gearing systems also incorporate the use of an outer ring gear or annulus, which meshes with …

Introduction to Gears 1. GEARS BYProf. NISHAL KADLI MESCOE PUNE 2. GEAR• Power transmission is the movement of energy from its place of generation to a location where it is applied to performing useful work• A gear is a component within a transmission device that transmits rotational force to another gear or device Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear

Straight Tooth Bevel Gears Worms and Worm Gears Material and Design Recommendations and Answers 1-Year Warranty on Full Gear Sets. Opened in 1995. Since 1995 Adobe Precision Gear has been open for business in Carlsbad NM and is a member of American Gear Manufactures Association (AGMA). Straight Tooth Bevel Gears Worms and Worm Gears Material and Design Recommendations and Answers 1-Year Warranty on Full Gear Sets. Opened in 1995. Since 1995 Adobe Precision Gear has been open for business in Carlsbad NM and is a member of American Gear Manufactures Association (AGMA).

Straight Tooth Bevel Gears Worms and Worm Gears Material and Design Recommendations and Answers 1-Year Warranty on Full Gear Sets. Opened in 1995. Since 1995 Adobe Precision Gear has been open for business in Carlsbad NM and is a member of American Gear Manufactures Association (AGMA). Helical gears are preferred for heavy load applications; Helical gears could be used to transmit the motion and power between two parallel shafts and also between two non parallel shafts. Helical gears will have more capability to transmit load between two parallel shafts as compared to similar module and equivalent width of spur gears.

Double-helical planetary gear set combines the merits of herringbone gear and planetary gear set, it has many high-quality features, such as: reliable transmission, smooth operation and so on. Double-helical planetary gear sets have been widely applied in heavy and high-speed mechanical transmission, especially in ship turbines, internal combustion engines. Find Herringbone Gears on GlobalSpec by specifications. Herringbone gears, also called double helical gears, are gear sets designed to transmit power through parallel or, less commonly, perpendicular axes. The unique tooth structure of a herringbone gear consists of two adjoining, opposite helixes that appear in the shape of the letter 'V'.

Herringbone gears are very similar to the double helical gear, but they do not have a gap separating the two helical faces. Herringbone gears are typically smaller than the comparable double helical, and are ideally suited for high shock and vibration applications. 2018-05-13 · Types of gear (Animation) by Basic Engineering In this video we are going to see different types of gears. Following types of gears are explained:- Spur gear Helical gear Herringbone gear Rack and

Lufkin™ transmissions for marine applications: Medium Speed Reverse Reduction brochure; Quality you can count on, expertise you need to succeed As the premier partner for industry-leading gearing solutions, BHGE has added the technology and expertise of Lufkin™ transmissions and Allen Gears Double-helical planetary gear set combines the merits of herringbone gear and planetary gear set, it has many high-quality features, such as: reliable transmission, smooth operation and so on. Double-helical planetary gear sets have been widely applied in heavy and high-speed mechanical transmission, especially in ship turbines, internal combustion engines.

Herringbone gear also allow for the use of larger diameter shaft for the same volumetric displacement and higher differential pressure capability. Application:-The most common application is in power transmission. They utilize curved teeth for efficient, high capacity power transmission. power transmission elements that determine the speed, torque, and di-rection of these types should be used for a partic-ular application. Table 1 compares these factors and relates them to the specific gear selections. This section on gearing and gear drives describes Herringbone gears — Teeth in these gears resemble the geometry of a

What are the advantages and disadvantages of Herringbone

Gearboxes Baker Hughes a GE Company. Herringbone and double-helical gears are helical gears with both left- and right-hand helices. A herringbone gear has no gap between the helices. A double-helical gear has a gap between the helices. External herringbone or double-helical gears have teeth that project outwards, whereas internal double-helical gears have teeth that project inwards., Gearbox Design and Application Overview Regardless of the initial conceptualization approach, engineering and design must identify the gearbox application, gear configurations / type and packaging requirements. Gear Motor Transmission Inertia Drive Calculator; Table of powers, speeds, transmission ratios, dimensions (orientation values) for Gearing.

What are herringbone gears used in? Quora

What are the advantages and disadvantages of Herringbone. Herringbone gears are very similar to the double helical gear, but they do not have a gap separating the two helical faces. Herringbone gears are typically smaller than the comparable double helical, and are ideally suited for high shock and vibration applications. https://en.m.wikipedia.org/wiki/Citro%C3%ABn_D5 2015-02-14 · A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring)..

Introduction to Gears 1. GEARS BYProf. NISHAL KADLI MESCOE PUNE 2. GEAR• Power transmission is the movement of energy from its place of generation to a location where it is applied to performing useful work• A gear is a component within a transmission device that transmits rotational force to another gear or device A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring).

Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications. Manufacturer of Transmission Gears - Herringbone Pinion, Spur Gear, MS Industrial Gear and Gear Wheel offered by Prarthana Industries Therefore, suitable for applications of engineering industry. Our valued clients can avail these products in different sizes and specifications as per their requirement. Yes! I am interested. MS Industrial Gear.

Chongqing Zhizhan Gear Transmission Co.,Ltd. specializes in the manufacturing of all kinds of high-precision Gleason and Klingelnberg format sprial bevel gears and gear shafts. Our company is located in Degan Industrial Park in Jiangjin district and … Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications.

Double helical gears are used in many applications such as cranes, fluid pumps and power transmission to the propulsion screws in military ships for a quieter and less vibration operation. Our maximum diameter of external double helical gear is 1370mm (54 inches) * maximum face width 250mm (10 inches) with 30 degree helix angle. Single vs double helical gears. be the appropriate choice for state-of-the-art applications that may require corrective characteristics of herringbone gear transmission,

2008-01-21 · Best Answer: #Herringbone gears are a type of double helical gear, meaning that they have both a left hand and right hand element to cancel thrust or side loading on their bearings. A true herringbone has a 30° helix angle, 20° transverse pressure angle, and an AGMA stub whole depth factor. They may have a center groove between the two hands, but this is not … Find Herringbone Gears on GlobalSpec by specifications. Herringbone gears, also called double helical gears, are gear sets designed to transmit power through parallel or, less commonly, perpendicular axes. The unique tooth structure of a herringbone gear consists of two adjoining, opposite helixes that appear in the shape of the letter 'V'.

2011-05-18 · Herringbone Gear Can Crusher Steve Garrison. Loading Herringbone or Chevron gears are stronger than spur gears and do not have any tendency to move along the axle even under heavy loads. Differences between herringbone gear and double helical gear are given here in table format. Each of them has specific features and is suitable for certain type of applications. A gear drive is preferred for power transmission over small distance. for specified power transmission, a thinner herringbone gear can be employed.

Manufacturer of Transmission Gears - Herringbone Pinion, Spur Gear, MS Industrial Gear and Gear Wheel offered by Prarthana Industries Therefore, suitable for applications of engineering industry. Our valued clients can avail these products in different sizes and specifications as per their requirement. Yes! I am interested. MS Industrial Gear. Additional Suppliers of Herringbone Gears. Affiliated Distributors Agnee Transmissions (I) Pvt Ltd Agro Engineers Akgears, LLC Akron Gear and Engineering American Gear & Engineering Area Distributors Inc. Atlanta Gear Works Avion Technologies Inc. Bearing Engineering Bearing Headquarters Company Bierens Machinefabrieken B.V. Brad Foote Gear

Helical gears: What are they and where are they used? November 22, 2017 By Danielle Collins Leave a Comment Helical gears and spur gears are two of the most common gear types and can be used in many of the same applications. Gearbox Design and Application Overview Regardless of the initial conceptualization approach, engineering and design must identify the gearbox application, gear configurations / type and packaging requirements. Gear Motor Transmission Inertia Drive Calculator; Table of powers, speeds, transmission ratios, dimensions (orientation values) for Gearing

Herringbone and double-helical gears are helical gears with both left- and right-hand helices. A herringbone gear has no gap between the helices. A double-helical gear has a gap between the helices. External herringbone or double-helical gears have teeth that project outwards, whereas internal double-helical gears have teeth that project inwards. 2000-11-16 · When two teeth on a helical gear system engage, the contact starts at one end of the tooth and gradually spreads as the gears rotate, until the two teeth are in full engagement. This gradual engagement makes helical gears operate much more smoothly and quietly than spur gears. For this reason, helical gears are used in almost all car transmissions.

Alibaba.com offers 1,928 herringbone gear products. About 23% of these are bevel gears, 15% are other gears, and 8% are spur gears. A wide variety of herringbone gear options are available to you, such as steel, stainless steel, and iron. The invention discloses a herringbone gear transmission mechanism of a gearbox. The herringbone gear transmission mechanism comprises a drive gear and a driven gear which are arranged in a gearbox body. The drive gear is connected to an output shaft in the gearbox body. The drive gear and the driven gear are herringbone gears. A limiting guide groove is formed in …

power transmission elements that determine the speed, torque, and di-rection of these types should be used for a partic-ular application. Table 1 compares these factors and relates them to the specific gear selections. This section on gearing and gear drives describes Herringbone gears — Teeth in these gears resemble the geometry of a 4. Planetary Gear Systems: This is one of the most interesting and complicated gear systems.The systems mainly constitutes of an internal gear, a pair of planet gears and a sun gear. This type of gearing is quite a complicated one which can be used …