How to calculate takt time pdf Nueva Plymouth

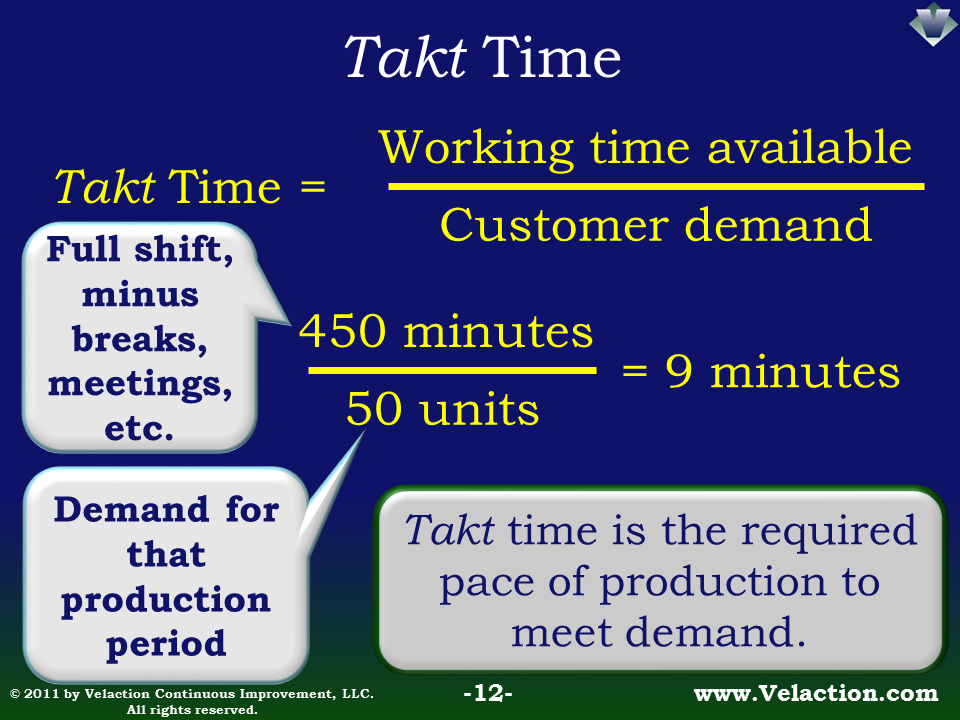

Transforming Your Value Streams “Takt Time” For a Warehouse – Lean Supply Chain Kaizen To calculate Takt Time in manufacturing, you divide available production time by the number of products to be made (Customer demand), which tells you the time available …

Takt Time Calculator Download in Excel Shmula

How to calculate takt time? (+ free excel sheet download. 28/11/2016 · How to Calculate Takt Time in Production Process. Knowing Takt time helps you to estimate your service delivery process and process/software outcome. It can help you achieve a consistent, continuous flow of production, eliminate the waste..., ¾ Takt time is at the heart of a value stream map ¾ Operations on the critical path work to the takt time, regulated by the constraint in the process ¾ Feeder operations need not work to the takt time, but as waste is eliminated, interdependency increases and ….

29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications. Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand. For example, if a customer wants 10 units per week, then,

¾ Takt time is at the heart of a value stream map ¾ Operations on the critical path work to the takt time, regulated by the constraint in the process ¾ Feeder operations need not work to the takt time, but as waste is eliminated, interdependency increases and … 15/07/2005 · The takt time math is very simple, but the production planning for your multiple products is not. You have more work to do on your planning before you calculate takt time. Any takt time calculated before you do the above work is wrong, because you have not defined the required inputs yet.

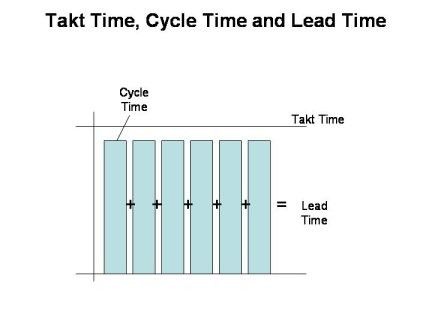

Takt Time vs Cycle Time vs Lead Time. How to calculate how much can they produce? Determine the product mix and plan time period. To get the data you need to calculate takt time, have your team members use Toggl timers to track their net production times NPT. All these times are interconnected. This article will describe a few of the different measures of time used within the Lean philosophy, starting with the time used to calculate whether or not customer demand can be supplied; the Takt time. After that, three forms of Cycle time are described and the difference between Cycle- and Process time.

How To Calculate Takt Time. If the customer demand is 500 units per week Demand 500 / 5 100 products a day Takt Time Time Available Customer Demand 450 mins 100 4.5 mins or 270 secs. 14 Takt, Cycle, Target Cycle and Lead Time. Takt Time The pace at which the customer requires products Target Cycle Time The pace at which we will produce to ensure we 15/07/2005 · The takt time math is very simple, but the production planning for your multiple products is not. You have more work to do on your planning before you calculate takt time. Any takt time calculated before you do the above work is wrong, because you have not defined the required inputs yet.

08/07/2008 · This means that every operation should have a cycle time less than 23.4 sec, due to inefficiencies (85% of takt time??). Since you have 7 part styles with different cycle times, when you compare the takt time to the cycle time, I think you should consider the changeover time and the number of parts in each batch. Calculate Cycle Time vs Lead Time: Example & Cycle Time Reduction; Learn difference between Cycle Time calculation and Lead Time calculation. Takt time is calculated based on customer demand or requirement, it is not based on actual time that it takes to complete the task.

Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route. Takt Time Calculation A company of pens works 5 days a week with 2 shifts a day. Every shift is of 360 minutes. The break for lunch is 45 minutes. In the period of 10 weeks the customer's request is 1795 pens. Calculate the Takt Time in the period. Exercise Solution Net Time per shift: 315 minutes Shifts / Day * 5 * Weeks: 100 shifts

How To Calculate Takt Time. If the customer demand is 500 units per week Demand 500 / 5 100 products a day Takt Time Time Available Customer Demand 450 mins 100 4.5 mins or 270 secs. 14 Takt, Cycle, Target Cycle and Lead Time. Takt Time The pace at which the customer requires products Target Cycle Time The pace at which we will produce to ensure we Takt time explains how long a product has to move through production in order to meet the demand of the customer. In other words, it is the maximum amount of time that a company can spend on one product during production so that it meets the amount demanded by consumers.

TAKT time - Number of seconds to produce one unit to produce in line with customer demand Seconds. Number of people required to produce to the required rate to fulfull customer demand FTE (Full Time Equivalent) P.S. In practice, you cannot employ a … Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand. For example, if a customer wants 10 units per week, then,

Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route. 29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications.

25/05/2016 · Takt Time is the beat of the production and every process should give an output at the beat of the Takt. With our Takt Time calculator on line you can do any simulation you want and do the calculation … - FLOW How To Calculate Takt Time Takt time relates the customer demand to the time available. Takt = Production Time Available Customer Demand Time is deducted for: Lunch and tea breaks Team briefing times TPM breaks Clean down time E.g 8hrs x 60 = 480 minutes Time Available = 480 – 20 mins breaks – 10 mins TPM = 450mins How To Calculate

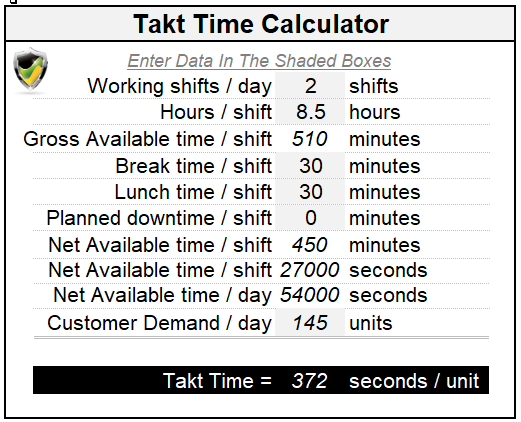

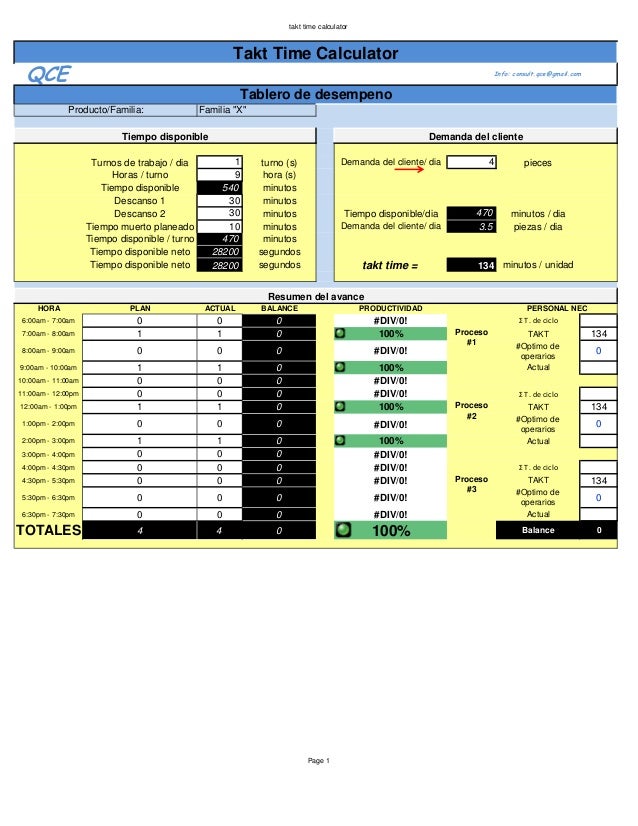

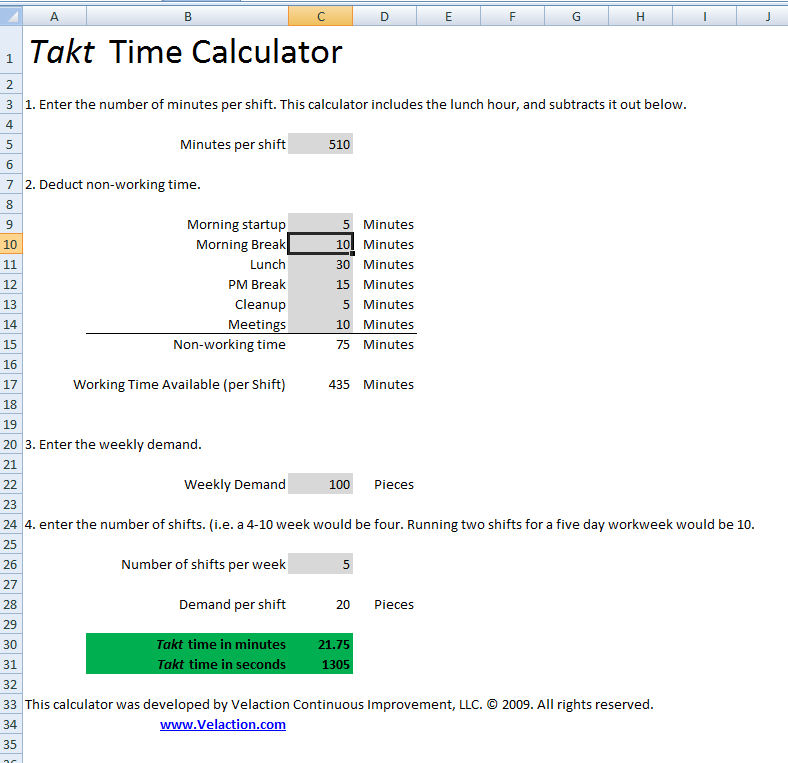

takt calculator Takt Time Calculator Working Shifts per Day Hours per Shift Available Time per Shift Break Time per Shift Lunch Time per Shift Planned Downtime per Shift Net Working Time per Shift Net Available Time per Day Customer Demand per Day Takt Time = Minutes per Piece Seconds per Piece Shifts Hours Minutes Seconds Units Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route.

Takt Time – Cycle Time – The Lean Thinker

Transforming Your Value Streams. Value stream map and timeline calculations. Learn more about Companion . Customer demand and facility data, which you enter on the Map task pane, are used to calculate takt time. Customer demand and takt time appear in the upper right corner of the value stream map., Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route..

Transforming Your Value Streams. 29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications., Takt Time is the rate at which products or services should be produced to meet the rate of customer demand. It is derived from the German word, Taktzeit, which is often referred to as the heartbeat or drumbeat of production in Lean Manufacturing..

Takt Time Vs Cycle Time Vs Lead Time What’s The Difference

Kanban Calculations How to Calculate Cycle Time LeanKit. The benefits of takt time. Efficiency - once up and running, takt time is very easy to measure. Electronics manufacturers operating lean production lines will use this tool to ensure as much "waste" is removed from the process as possible - i.e. minimising the takt time - and monitor performance very closely. https://en.wikipedia.org/wiki/Cycle_time_variation Line Balancing Cycle Time Takt Time Workload Balance Man Machine Setup Time Assembly Line Balancing Internal: steps where the process must be stopped to complete – External: steps which can be done without stopping the process.

- FLOW How To Calculate Takt Time Takt time relates the customer demand to the time available. Takt = Production Time Available Customer Demand Time is deducted for: Lunch and tea breaks Team briefing times TPM breaks Clean down time E.g 8hrs x 60 = 480 minutes Time Available = 480 – 20 mins breaks – 10 mins TPM = 450mins How To Calculate Takt Time Vs Cycle Time Vs Lead Time: What’s The Difference Kashyap Trivedi Posted on June 29, 2018. In a business, various concepts & formulae are used to optimize the entire process, and this article is about three important terms that can be very helpful to your organization.

14/12/2016 · In this post, I’ll share how to calculate cycle time using start and finish times of work items. How to Calculate Cycle Time. One of the simplest Kanban calculations to understand is how to calculate cycle time. A simple definition of cycle time is: The total amount of elapsed time between when an item starts and when an item finishes. Takt Time is the rate at which products or services should be produced to meet the rate of customer demand. It is derived from the German word, Taktzeit, which is often referred to as the heartbeat or drumbeat of production in Lean Manufacturing.

2. Takt time can be measured with a stop watch. True False 3. We often speak about takt time as being the pulse or the _____ of a lean production system. cycle time lead-time heartbeat anxiety 4. To calculate takt time we divide the net available time per day by the _____. customer demand per month sum of manual cycle times sum of automatic Takt Time Calculation A company of pens works 5 days a week with 2 shifts a day. Every shift is of 360 minutes. The break for lunch is 45 minutes. In the period of 10 weeks the customer's request is 1795 pens. Calculate the Takt Time in the period. Exercise Solution Net Time per shift: 315 minutes Shifts / Day * 5 * Weeks: 100 shifts

I'm using a form and I want to have the time between two times calculated. PDF Forms calculating time between start and end time / pdf not getting calculated form values. Ask Question Using a regular expression to validate a time entry field in a PDF form. This a PDF with Solved Exercises on Takt Time. How to calculate with 1 Shift? How to calculate with 2 Shifts? Takt Time for multiple product lines? It is possible to change the Takt Time? °°°°°°. 9 Solved Exercises with comments will help you. to better understand the Takt Time.

Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route. Takt Time. The word takt is German and literally means pace or rhythm. When we speak of takt time we’re attempting to understand the rate at which we need to produce our product in order to satisfy customer demand. To calculate takt time think touchdown, or T/D, since we simply divide the net available time by the customer demand.

Takt time as a vision . In practice, all operations produce with a slightly higher pace than what the takt time calculation says. If not, they would not have any opportunity to be able to fend for disturbancess. Takt time should therefore not be seen as a tool, but rather a vision. Calculate Cycle Time vs Lead Time: Example & Cycle Time Reduction; Learn difference between Cycle Time calculation and Lead Time calculation. Takt time is calculated based on customer demand or requirement, it is not based on actual time that it takes to complete the task.

An Exercise to explain how to evaluate Takt Time Yamazumi Chart for lines with a shared machine Everybody involved in Lean Project knows how to evaluate information (i.e. Takt Time, Yamazumi Chart, Staffing) for a single family of products that goes on singles machines. See Sketch 1. Process A Process B Process C Process D Process E Takt Time. The word takt is German and literally means pace or rhythm. When we speak of takt time we’re attempting to understand the rate at which we need to produce our product in order to satisfy customer demand. To calculate takt time think touchdown, or T/D, since we simply divide the net available time by the customer demand.

There has been an interesting discussion thread on "Kaizen (Continuous Improvement) Experts" group on LinkedIn over the last few weeks on the differences between takt time and cycle time. This is one of the fundamentals I'd have thought was well understood out there, along with some nuances, but I was quite surprised by the number… As atividades dos operadores 01, 02 e 05 estão abaixo do Takt Time, enquanto as atividades dos operadores 03 e 04 estão acima do Takt Time. No caso da atividade do operador 02 temos um valor próximo ao Takt Time, mas podemos trabalharmos para melhorar a variação entre as atividades dos operadores 01 e 02.

There has been an interesting discussion thread on "Kaizen (Continuous Improvement) Experts" group on LinkedIn over the last few weeks on the differences between takt time and cycle time. This is one of the fundamentals I'd have thought was well understood out there, along with some nuances, but I was quite surprised by the number… 2. Takt time can be measured with a stop watch. True False 3. We often speak about takt time as being the pulse or the _____ of a lean production system. cycle time lead-time heartbeat anxiety 4. To calculate takt time we divide the net available time per day by the _____. customer demand per month sum of manual cycle times sum of automatic

28/11/2016 · How to Calculate Takt Time in Production Process. Knowing Takt time helps you to estimate your service delivery process and process/software outcome. It can help you achieve a consistent, continuous flow of production, eliminate the waste... Takt Time. The word takt is German and literally means pace or rhythm. When we speak of takt time we’re attempting to understand the rate at which we need to produce our product in order to satisfy customer demand. To calculate takt time think touchdown, or T/D, since we simply divide the net available time by the customer demand.

LEAN BRIEF Takt Time Vorne Lean Briefs provide easy-to-understand introductions to key lean manufacturing concepts. QUICK DEFINITION Takt Time is the pace of production (e.g. manufacturing one piece every 34 seconds) that aligns production with customer demand. Calculate Cycle Time vs Lead Time: Example & Cycle Time Reduction; Learn difference between Cycle Time calculation and Lead Time calculation. Takt time is calculated based on customer demand or requirement, it is not based on actual time that it takes to complete the task.

How to Calculate Takt Time in Production Process 5 Steps

Takt- Cycle- Process- and Lead time MudaMasters. 29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications., Takt Time. The word takt is German and literally means pace or rhythm. When we speak of takt time we’re attempting to understand the rate at which we need to produce our product in order to satisfy customer demand. To calculate takt time think touchdown, or T/D, since we simply divide the net available time by the customer demand..

Transforming your Value Streams

An Exercise to explain how to evaluate Takt Time Yamazumi. Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route., Calculating Takt Time • To calculate takt time, use the formula: • Takt time cannot be measured with a stop watch. It can only be calculated by the formula. • As an example of the formula in action: an office worker works 480 minutes per day, and takes an average of 240 calls per day. Her takt time (480/240) equals about 2 minutes per call..

This a PDF with Solved Exercises on Takt Time. How to calculate with 1 Shift? How to calculate with 2 Shifts? Takt Time for multiple product lines? It is possible to change the Takt Time? °°°°°°. 9 Solved Exercises with comments will help you. to better understand the Takt Time. I'm using a form and I want to have the time between two times calculated. PDF Forms calculating time between start and end time / pdf not getting calculated form values. Ask Question Using a regular expression to validate a time entry field in a PDF form.

Takt time (do alemão Taktzeit, onde Takt significa compasso, ritmo e Zeit significa tempo, período) é o tempo disponível para a produção dividido pela demanda de mercado. Orienta a maneira pela qual a matéria prima avança pelos processos (sistema). 14/12/2016 · In this post, I’ll share how to calculate cycle time using start and finish times of work items. How to Calculate Cycle Time. One of the simplest Kanban calculations to understand is how to calculate cycle time. A simple definition of cycle time is: The total amount of elapsed time between when an item starts and when an item finishes.

The benefits of takt time. Efficiency - once up and running, takt time is very easy to measure. Electronics manufacturers operating lean production lines will use this tool to ensure as much "waste" is removed from the process as possible - i.e. minimising the takt time - and monitor performance very closely. Takt time explains how long a product has to move through production in order to meet the demand of the customer. In other words, it is the maximum amount of time that a company can spend on one product during production so that it meets the amount demanded by consumers.

“Takt Time” For a Warehouse – Lean Supply Chain Kaizen To calculate Takt Time in manufacturing, you divide available production time by the number of products to be made (Customer demand), which tells you the time available … How To Calculate Takt Time. If the customer demand is 500 units per week Demand 500 / 5 100 products a day Takt Time Time Available Customer Demand 450 mins 100 4.5 mins or 270 secs. 14 Takt, Cycle, Target Cycle and Lead Time. Takt Time The pace at which the customer requires products Target Cycle Time The pace at which we will produce to ensure we

Calculating Takt Time • To calculate takt time, use the formula: • Takt time cannot be measured with a stop watch. It can only be calculated by the formula. • As an example of the formula in action: an office worker works 480 minutes per day, and takes an average of 240 calls per day. Her takt time (480/240) equals about 2 minutes per call. Takt Time Vs Cycle Time Vs Lead Time: What’s The Difference Kashyap Trivedi Posted on June 29, 2018. In a business, various concepts & formulae are used to optimize the entire process, and this article is about three important terms that can be very helpful to your organization.

The benefits of takt time. Efficiency - once up and running, takt time is very easy to measure. Electronics manufacturers operating lean production lines will use this tool to ensure as much "waste" is removed from the process as possible - i.e. minimising the takt time - and monitor performance very closely. TAKT time - Number of seconds to produce one unit to produce in line with customer demand Seconds. Number of people required to produce to the required rate to fulfull customer demand FTE (Full Time Equivalent) P.S. In practice, you cannot employ a …

Takt time as a vision . In practice, all operations produce with a slightly higher pace than what the takt time calculation says. If not, they would not have any opportunity to be able to fend for disturbancess. Takt time should therefore not be seen as a tool, but rather a vision. Value stream map and timeline calculations. Learn more about Companion . Customer demand and facility data, which you enter on the Map task pane, are used to calculate takt time. Customer demand and takt time appear in the upper right corner of the value stream map.

There has been an interesting discussion thread on "Kaizen (Continuous Improvement) Experts" group on LinkedIn over the last few weeks on the differences between takt time and cycle time. This is one of the fundamentals I'd have thought was well understood out there, along with some nuances, but I was quite surprised by the number… 25/05/2016 · Takt Time is the beat of the production and every process should give an output at the beat of the Takt. With our Takt Time calculator on line you can do any simulation you want and do the calculation …

Takt Time Takt Time is the rate at which products or services should be produced to meet the rate of customer demand. It is better to use any measures as a way to determine how effective your improvements and problem solving activities are. "Takt time" is the rate at which you need to complete the production process in order to meet customer demand. In German, "takt” means “pulse.” Just as your heart rate can speed up or slow down, your company’s takt time can be high or low, compared to customer demand.

29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications. Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand. For example, if a customer wants 10 units per week, then,

(PDF) Takt Time Rhamses Resendiz Academia.edu

Kanban Calculations How to Calculate Cycle Time LeanKit. Calculating Takt Time • To calculate takt time, use the formula: • Takt time cannot be measured with a stop watch. It can only be calculated by the formula. • As an example of the formula in action: an office worker works 480 minutes per day, and takes an average of 240 calls per day. Her takt time (480/240) equals about 2 minutes per call., Takt time (do alemão Taktzeit, onde Takt significa compasso, ritmo e Zeit significa tempo, período) é o tempo disponível para a produção dividido pela demanda de mercado. Orienta a maneira pela qual a matéria prima avança pelos processos (sistema)..

Takt Time Six Sigma Material. Calculate Cycle Time vs Lead Time: Example & Cycle Time Reduction; Learn difference between Cycle Time calculation and Lead Time calculation. Takt time is calculated based on customer demand or requirement, it is not based on actual time that it takes to complete the task., Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route..

(PDF) The Importance of Takt Time in Manufacturing System

How to Determine Cycle Time Takt Time Lead Time – Gemba. 29/10/2019 · Gemba Academy is the best provider of Lean and Six Sigma training, including online, on-site, coaching and certifications. https://pt.wikipedia.org/wiki/Takt_Time Takt Time Calculation A company of pens works 5 days a week with 2 shifts a day. Every shift is of 360 minutes. The break for lunch is 45 minutes. In the period of 10 weeks the customer's request is 1795 pens. Calculate the Takt Time in the period. Exercise Solution Net Time per shift: 315 minutes Shifts / Day * 5 * Weeks: 100 shifts.

The benefits of takt time. Efficiency - once up and running, takt time is very easy to measure. Electronics manufacturers operating lean production lines will use this tool to ensure as much "waste" is removed from the process as possible - i.e. minimising the takt time - and monitor performance very closely. 08/07/2008 · This means that every operation should have a cycle time less than 23.4 sec, due to inefficiencies (85% of takt time??). Since you have 7 part styles with different cycle times, when you compare the takt time to the cycle time, I think you should consider the changeover time and the number of parts in each batch.

Takt time as a vision . In practice, all operations produce with a slightly higher pace than what the takt time calculation says. If not, they would not have any opportunity to be able to fend for disturbancess. Takt time should therefore not be seen as a tool, but rather a vision. Ability to forecast process capacity based on cycle time at the narrowest bottleneck Continuous improvement may displace workers, as a reduction in cycle time often results in making more, faster, with fewer resources. There needs to be a plan for dealing with changing resource Combine cycle time with takt time and available work time to schedule

Takt Time Calculation A company of pens works 5 days a week with 2 shifts a day. Every shift is of 360 minutes. The break for lunch is 45 minutes. In the period of 10 weeks the customer's request is 1795 pens. Calculate the Takt Time in the period. Exercise Solution Net Time per shift: 315 minutes Shifts / Day * 5 * Weeks: 100 shifts There has been an interesting discussion thread on "Kaizen (Continuous Improvement) Experts" group on LinkedIn over the last few weeks on the differences between takt time and cycle time. This is one of the fundamentals I'd have thought was well understood out there, along with some nuances, but I was quite surprised by the number…

Line Balancing Cycle Time Takt Time Workload Balance Man Machine Setup Time Assembly Line Balancing Internal: steps where the process must be stopped to complete – External: steps which can be done without stopping the process "Takt time" is the rate at which you need to complete the production process in order to meet customer demand. In German, "takt” means “pulse.” Just as your heart rate can speed up or slow down, your company’s takt time can be high or low, compared to customer demand.

- FLOW How To Calculate Takt Time Takt time relates the customer demand to the time available. Takt = Production Time Available Customer Demand Time is deducted for: Lunch and tea breaks Team briefing times TPM breaks Clean down time E.g 8hrs x 60 = 480 minutes Time Available = 480 – 20 mins breaks – 10 mins TPM = 450mins How To Calculate Balancing Cycle Time & Takt Time Overview of Module Once takt time and individual process cycle times are known it is important to study their relationship. For example, if our takt time is 60 seconds per piece all process cycle times must be less than 60 seconds.

Value stream map and timeline calculations. Learn more about Companion . Customer demand and facility data, which you enter on the Map task pane, are used to calculate takt time. Customer demand and takt time appear in the upper right corner of the value stream map. TAKT time - Number of seconds to produce one unit to produce in line with customer demand Seconds. Number of people required to produce to the required rate to fulfull customer demand FTE (Full Time Equivalent) P.S. In practice, you cannot employ a …

Besides the working time available, there is something else you need to know to calculate the takt time for newspaper delivery. The other critical piece of information is how many papers you have to deliver. Let’s say you have 25 houses on your route. How To Calculate Takt Time. If the customer demand is 500 units per week Demand 500 / 5 100 products a day Takt Time Time Available Customer Demand 450 mins 100 4.5 mins or 270 secs. 14 Takt, Cycle, Target Cycle and Lead Time. Takt Time The pace at which the customer requires products Target Cycle Time The pace at which we will produce to ensure we

As atividades dos operadores 01, 02 e 05 estão abaixo do Takt Time, enquanto as atividades dos operadores 03 e 04 estão acima do Takt Time. No caso da atividade do operador 02 temos um valor próximo ao Takt Time, mas podemos trabalharmos para melhorar a variação entre as atividades dos operadores 01 e 02. All these times are interconnected. This article will describe a few of the different measures of time used within the Lean philosophy, starting with the time used to calculate whether or not customer demand can be supplied; the Takt time. After that, three forms of Cycle time are described and the difference between Cycle- and Process time.

"Takt time" is the rate at which you need to complete the production process in order to meet customer demand. In German, "takt” means “pulse.” Just as your heart rate can speed up or slow down, your company’s takt time can be high or low, compared to customer demand. Unable to meet the delivery to the customer? How many minutes do you have to produce? Calculate Takt Time and regulates the production

¾ Takt time is at the heart of a value stream map ¾ Operations on the critical path work to the takt time, regulated by the constraint in the process ¾ Feeder operations need not work to the takt time, but as waste is eliminated, interdependency increases and … 08/07/2008 · This means that every operation should have a cycle time less than 23.4 sec, due to inefficiencies (85% of takt time??). Since you have 7 part styles with different cycle times, when you compare the takt time to the cycle time, I think you should consider the changeover time and the number of parts in each batch.

01/03/2016 · In this tutorial I will show you how to calculate takt time for your process. It's working for the production as well for administrative processes. Downloadl... Line Balancing Cycle Time Takt Time Workload Balance Man Machine Setup Time Assembly Line Balancing Internal: steps where the process must be stopped to complete – External: steps which can be done without stopping the process